Inside Story

How to split things apart, how to connect things together?

"Deciding whether to put the various

camera functions in the body or in

the camera unit and then figuring

out how to do that was a long process

of repeated trial and error." (Susumu

Katagiri)

"With the interchangeable unit system, we had to take a digital camera system originally housed in a single case and divide it in two. Looking back at the development period, after the decision was made to adopt the interchangeable unit system, we spent quite a long time considering how to go about deciding the details of what should go where," said Susumu Katagiri, who directed the overall development effort as a member of the Promotion Group of the Personal Multimedia Products Company ICS Design Office.

In the repetitive process of investigating such things as camera unit and body connection methods, there were many questions to be answered. For example: What roles should the camera unit and body each play? How should the circuit boards controlling electrical functions be positioned in the camera unit and body? For the software processing signals and data, how far should the processing go in the camera unit, and from where should the processing start in the body?

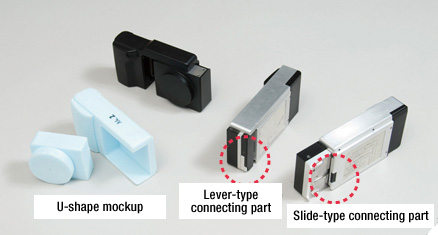

"Initially we also considered a U shape," Katagiri said as he lined up body and camera unit mockups. With the U shape, the camera unit slides completely inside the body. "When we considered the development of units other than camera units, however, we realized that the space limitations inherent in the U shape would restrict our more adventurous options in unit design. So we chose the current GXR body shape instead," Katagiri explained. The connection method also required considerable investigation. Should the user pull a lever to take out the unit? Should the connecting part be on the camera unit or the body? "We made prototypes and everybody tried operating them, with the final decision being to put it on the body," said Katagiri.

For a reliable feel in operation

Considerable attention was paid to the feel of camera unit insertion into the body, such as having a click sound so the user senses that the operation is complete. "We wanted something resembling the feel when lenses are changed on an SLR camera so that users are confident that a good connection has been made. The hard and abrupt feel of components striking against each other lowers reliability from both a mechanical perspective and as perceived by the user. To avoid this, we placed a rubber cushion on one side of the joint, and by leaving some play on one side of the connector we found a way to absorb slippage in the connecting part," said Katagiri. The reliability of the connection has been confirmed in testing attachment/removal more than 100,000 times. On the A12 there is an internal lens hood. To make it easy to take out and put back in, processing was done to raise the surface of the movable part.

Smooth lens hood movement achieved with processing to raise the inside surface.

The physical separation of body and camera unit had a major influence on the internal layout. "Until the GXR, we always tried to make the camera as small as possible with a layout that used even the smallest gaps so that everything would fit into a single body. However, with the interchangeable unit system, it was necessary to physically segregate parts between the body and camera unit. It was quite a challenge to do this while at the same time striving for compactness," said Katagiri. The flash is one example. In the internal layout of past camera designs, the flash was an L shape, part of which protruded into the space next to the lens. With the interchangeable unit system, however, the L shape could not be used. In order to put the flash entirely inside the body, it was necessary to change to a thin, flat shape so the staff in charge of the mechanics went through a long process of trial and error.

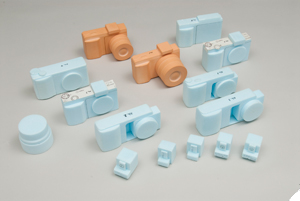

Many different mockups were prepared

- *Lens focal lengths in the text are all converted to 35 mm film camera equivalents.