Though it is hard to imagine from its impressive appearance, the PENTAX K-1 also feels very comfortable in the hand. This is hardly surprising, because it is only a little larger than the PENTAX K-3, which is equipped with a smaller, APS-C-size image sensor. It is common knowledge in camera development that, the smaller the size of the camera you’re trying to develop, the more technically difficult it becomes. PENTAX engineers, however, decided to accept the challenge of accomplishing this demanding task.

“In terms of camera size, the target we focused on was the very popular APS-C-size digital SLR cameras,” recalled one of the development team members. “We immediately started research into how we could fit a 35mm full-frame image-sensor unit in such a small space.”

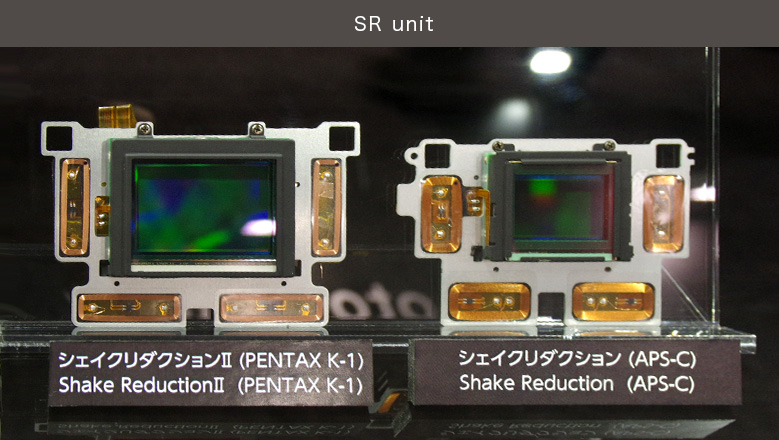

Current PENTAX digital SLR models provide an in-body SR (Shake Reduction) mechanism as one of the main features. To develop the PENTAX K-1, the team needed to efficiently drive a full-frame image sensor, with an imaging area twice the size of an APS-C-size camera, without making the size of the SR unit much larger.

Large coils and magnets were needed to generate greater driving force. How could they minimize the size and weight of these components? The answer the engineers came up with was to change conventional coils and magnets to slender ones and increase the capacity of the coils by winding more coils onto magnetic cores. One new attempt was the integration of magnet field simulation technology into the design process. They foresaw that, by optimizing the shape of the plates, coils and magnets, they could prevent the magnet field from escaping from the interior of the unit and make the most of the generated driving force.

Nearly one year after the engineers started developing the new SR unit, they finally figured out the solution. However, this was only the beginning of their painstaking efforts. Even though they succeeded in downsizing the SR unit, the total weight of the center plate, including the image sensor, circuit boards and coils, was almost 40 percent heavier than that of the K-3. Naturally, it also generated greater inertia, which made accurate position control of the SR unit more difficult. The PENTAX K-1’s Pixel Shift Resolution System also demanded high-precision position control, so that it could shift the SR unit by a single pixel.

Thanks to their hard work, the final SR unit was almost equal in width to that of the K-3. After joining it together with the battery chamber, it fit the width of the PENTAX K-1’s body perfectly.

Exacting demands promoted technological advancement

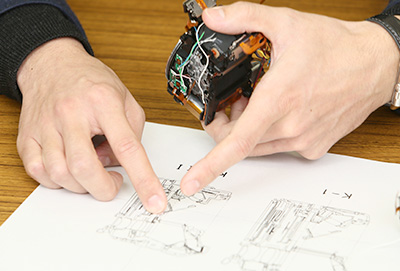

At the same time, the engineers in charge of developing a new mirror-driving mechanism faced the difficulty of designing the ideal mechanism from the very beginning. The space given to them was simply too small. Although they were initially hoping to adopt a simple mechanism that drove the mirror along a single axis of rotation, they immediately found out that the installation of such a mechanism would be impossible.

There were two reasons behind this. The first was that the PENTAX K-1 had no spare room in its fringe back — the distance from the imaging plane to the lens mount. Since the fringe back is the base of all K-mount lenses, it is unchangeable. In the case of digital cameras, however, a filter is placed in front of the image sensor. Coupled with the thickness of the SR unit, the shutter unit must be offset toward the lens mount. As a result, the distance from the lens mount to the shutter becomes shorter.

The second reason was PENTAX’s insistence in providing a nearly 100-percent field of view. In order to assure a light flux large enough for such a wide-view finder, the camera must be equipped with a large main mirror. Since the PENTAX K-1’s SR unit shifted the image sensor horizontally and vertically, however, its shutter window became larger. In order to cover such a large opening, the main mirror had to be driven over a greater distance.

“In this case, the main mirror bumped against the lens mount,” explained one of the team members.“With some lenses, the rear optical elements may penetrate into the mirror box. In order to design a lens mount that could accommodate this problem, we decided to adopt a link mechanism in the earliest stages of development.”

In the link mechanism, the pivot shifts its position as the mirror swings up and down. Since it requires a complex mechanism, very few cameras use it these days. The task assigned to the PENTAX engineers was how to refine and advance this mechanism to meet today’s demands.

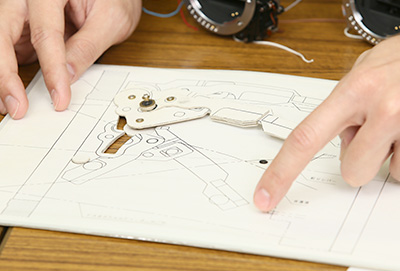

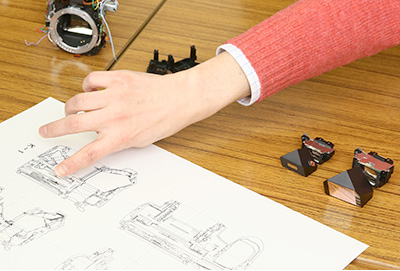

On one engineer’s desk, you can still find the paper model of the mechanism he created for team discussions. His paper model was helpful for the team members in visualizing the mirror movement, and greatly contributed in drawing them to the conclusion: the pivot of the main mirror would be positioned inside the shutter window before exposure, and would be lifted diagonally and backwards as the mirror swung up. This action would be regulated by a mechanism consisting of a motor, cams and levers.

What makes this mechanism so special is its remarkable position control accuracy since the lever is used to support the pivot, and the lack of positioning errors since no spring is used. “By using the advantages of the link mechanism and optimizing the motor’s regulation and transmission mechanisms, we succeeded in minimizing mirror bounce caused at the swing-down position,” said an engineer in charge of mirror mechanism development. In fact, the PENTAX K-1’s mirror bounce is even smaller than that of the APS-C-sized PENTAX K-3, which is theoretically easier to regulate because of its lighter mirror. In the end, the PENTAX engineers gave birth to the innovative Floating Mirror Structure, which drives a large mirror efficiently in a limited space, without the aid of an additional bounce-regulation mechanism or damper.

No compromises made, to assure a clear view of the viewfinder

The main mirror is not the only component affected by the larger image sensor of a full-frame camera. The finder optics, and the pentaprism in particular, also become larger in size. One engineer in charge of finder development was devastated after he finished an experiment in which he installed the smallest pentaprism that could cover the entire light flux on a test model. “Since there were internal reflections on the prism’s side surfaces, some light escaped from the finder’s field of view,” he says. “It was a question of the prism’s size and shape.”

What kind of treatment could be made to the prism’s side surfaces to assure a clear field of view while minimizing the finder’s size? In search of the best solution, he set out to make fine adjustments to the prism’s size and shape.

Including its prism, the PENTAX K-1 has completely new finder optics. Because of its wide field of view, distortion becomes more noticeable. There was no way PENTAX could name the PENTAX K-1 a flagship model of the K-series SLR cameras if users noticed distortion along the edges of the image field whenever they shift their point of view.

This engineer then directed his attention to the lens positioned directly underneath the prism. Normally, a condenser lens is placed at this position to make the finder’s field of view brighter. By processing this lens into an aspherical optical element, he succeeded in minimizing distortion as expected, without the need of more complex eyepiece optics.

Following this success, he quickly turned his attention to the transparent LCD viewfinder display placed underneath it. By applying the PENTAX-original AR (Anti-Reflection) coating to both sides of the display, he improved its light transmittance. An ordinary transparent LCD display has a disadvantage in terms of brightness, but the PENTAX K-1’s display assures a high-quality viewfinder image as clear and bright as that of the PENTAX K-3.

Despite its compact dimensions, the PENTAX K-1 weighs true to its full-frame design when held in your hand. This weight is the proof of the PENTAX engineers’ devotion and enthusiasm in developing a camera that exceeds the conventional wisdom of the camera industry.