Challengers

II. High-grade viewfinder system

Designed to achieve high standards

Challengers

II. High-grade viewfinder system

Designed to achieve high standards

Moriyasu Kanai

Optical Designer

Shinichiro Sanada

Mechanical Designer

Hisaya Yamamoto

Pentaprism Production Engineer

“We took on the challenge of developing a new optical viewfinder,

one that would surpass the performance of the PENTAX K-1.”

Kanai: In developing the optical viewfinder system for the PENTAX K-3 Mark III, we set very high standards right from the beginning of the product planning process.

That is what kept us going, as we worked over many years to achieve this challenging goal.

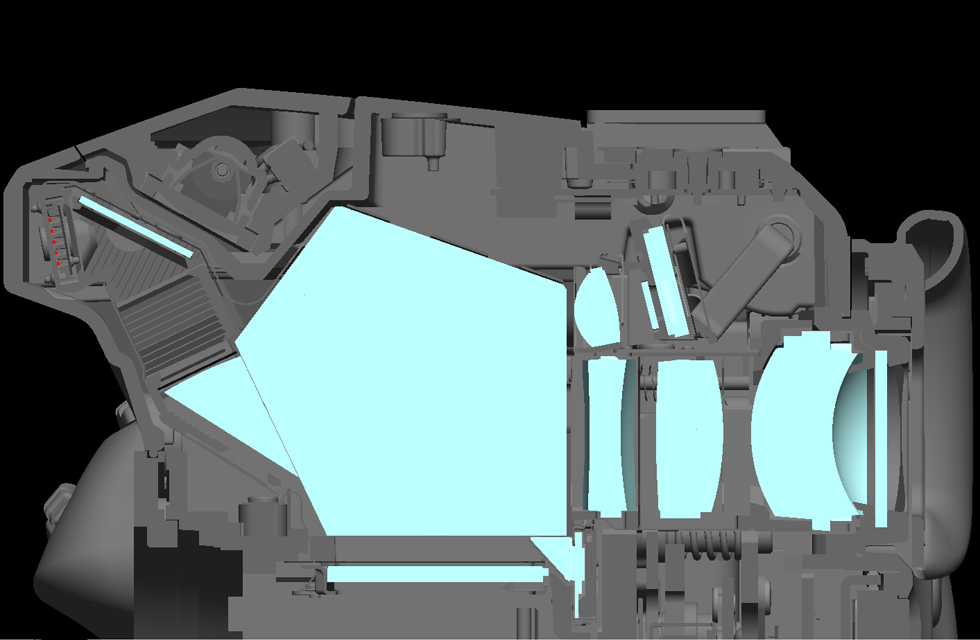

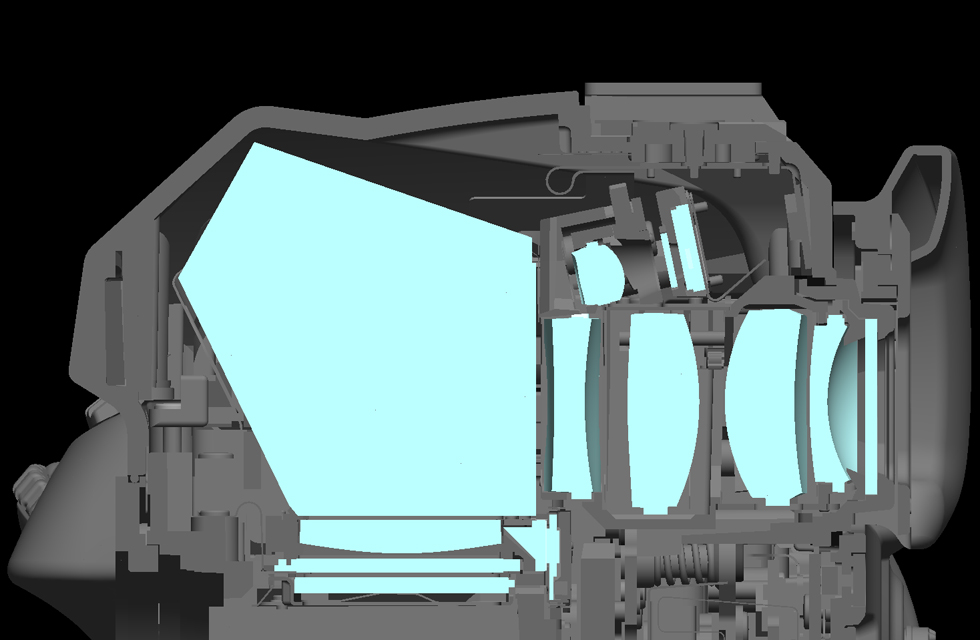

Sanada: The PENTAX K-3 Mark III’s viewfinder system has many distinctive features. However, we felt that the performance of the optical viewfinder would be the one factor that would truly set the value of the new camera. Most people interested in photography know that an APS-C-format camera has a viewfinder image that is smaller than that of a full-frame model. To provide a larger image, then, we had to resolve a number of issues — many which aren’t even listed in the specification sheet — as well as improving the viewfinder magnification.

Kanai: In principle, designing optics can be described as the task of balancing conflicting factors. The eye relief length is a trade-off with a higher viewfinder magnification. No matter how high the magnification of the image appearing on the focusing screen, the viewfinder is worthless if the photographer has to press the eye tightly on the viewfinder eyepiece and take a glance around the image field. We wanted instead to design a viewfinder providing the entire image field at one glance, while delivering a large viewfinder image. The key to solving these two conflicting factors was the development of a pentaprism made of high-refraction glass.

Yamamoto: It was only after we began developing this new pentaprism, though, that we realized that we were faced with a formidable task, especially at the processing and assessment stages. High-refraction glass is a highly rigid and fragile material. It was extremely hard work to cut the prism’s edges at specific angles. Initially, we were planning to develop and process this pentaprism at our main pentaprism production factory in Vietnam, and started testing more than 200 production methods. But things didn’t go well.

Of course, when we relocated our pentaprism production facility from Japan to Vietnam, this also involved transferring our expertise and craftsmanship. It’s usually the case in situations such as this that Japanese engineers visit the overseas factory and go through a detailed, repeated verification process with the local staff. Because of the coronavirus pandemic, however, it was impossible for us to make this trip. In the end, we decided to set up a new facility in Japan where our engineering team could develop the technologies necessary to perfect the finishing process, the production step which demanded the largest amount of time. For instance, our engineers experimented with many different production methods and minute testing conditions, finding solutions through a trial-and-error approach in the end.

Kanai: The viewfinder’s performance cannot be assessed merely by obvious factors, such as the image size, ease of focusing, and brightness. Other important factors which assist the photographer in concentrating on the image-shooting process include: a lack of ghost images; the rendition of natural, true-to-life colors; and a jet-black frame surrounding the image field.

Sanada: When I took the first look through the viewfinder of the prototype model, the large viewfinder image was the only thing that stood out. Everything else was well below my expectations. So we worked even harder to improve on what was missing. We were especially focused on the color rendition of the viewfinder image, and a jet-black frame surrounding the image field. We experimented with many different types of coating, and repeatedly reviewed the shape of the pentaprism to minimize the adverse effect of reflections.

This product incorporates a transparent LCD monitor, which provides a large amount of data in the viewfinder window. Conventional transmissive LCD systems tend to darken the viewfinder image, but the PENTAX K-3 Mark III features a number of new ideas and innovative components to deliver a viewfinder image that is even brighter than that of the PENTAX K-3 II.

Kanai: As one of the designers of this new viewfinder system, I am very thankful to Mr. Yamamoto and other members of the production technology team, as well as those working at the production factory, for making the mass production of the high-refraction glass pentaprism possible.

Yamamoto: We overcame many difficulties to reach the point where we stand today. I’m very proud of our accomplishment. I hope that you will have the chance to take this new camera in hand and have a close look at this optical viewfinder.